Off-site manufacture or construction is a staple of the Self-build industry, with timber-frame homes typically being built in factories. This means your home could be built on the other side of the country from your plot – or even in Europe.

Often referred to as package, prefabricated or kit homes, timber-frame homes built offsite offer a host of advantages to building onsite in the conventional manner. The route is neater, faster, less wasteful and less prone to site delays due to weather or malicious damage. In addition, offsite manufacturing allows for precise engineering that makes building technical homes easier.

Where this really comes into its own is incorporating highly environmental credentials, making offsite construction the logical choice for anyone working to create an airtight home or to Passivhaus (passive house standards). Insulation is often fitted in the factory, and the completed constructions usually come with membranes and even service channels in place in walls, roofs and ceilings.

But the drawback of offsite construction is that your home is fabricated at the factory, assembled and then disassembled to allow for it to be loaded on a flat-bed truck for delivery.

Delivery contributes to time in arrival on site, can be an issue at a site with restricted access, contributes to the carbon impact of shipping large components and often needs a dedicated installation team that will erect the home on site.

Flying factories – keeping building local

But a new breed of flying-factories is bringing the benefits of building offsite to anyone wanting an owner-commissioned home, with factories being temporarily created at the building location.

Graven Hill, the UK’s largest Self/Custom Build site, has become the testing ground of this new approach, with several companies manufacturing homes on site using flying factories.

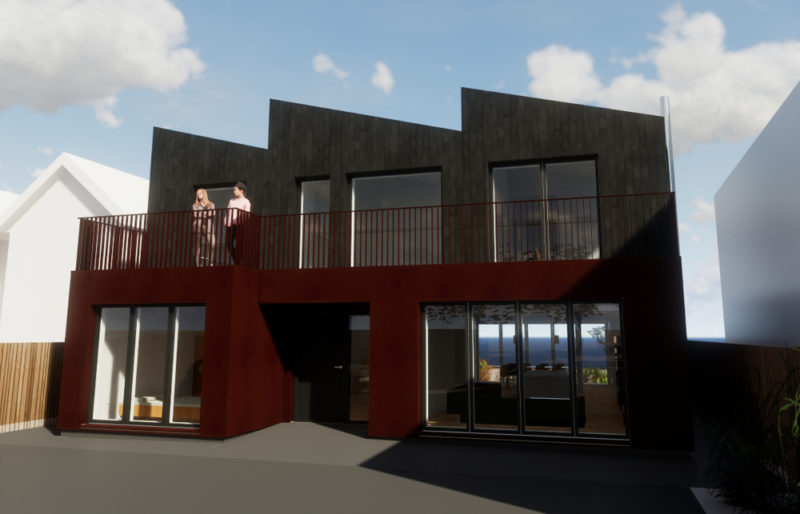

Facit Homes is constructing a home at Graven Hill (above), using its mobile production facility (main picture), which uses a shipping container that’s been converted to a workshop. This is delivered onsite, and then uses a computerised cutting machine to cut and build panels on site which are used to fabricate the house. In fact, its system was honoured with a Queen’s Award for Enterprise this year, for its innovative approach to housing design that involves onsite manufacturing.

Beattie Passive’s flying factory (below) is also being used to build a range of homes at Graven Hill, including Tailored Finish terraced houses, compact Coach Houses and individual self-builds

In addition, Beattie Passive is the preferred Passivhaus build system provider at Graven Hill, offering a Zero Carbon build with near zero energy bills, built locally by people working in the onsite flying factory.

While offering the opportunity to Self-build, Graven Hill is technically a Custom Build development in that anyone wishing it build there is working with the Graven Hill Village Development Company (GHVDC), which acts as an enabler.

As an enabler, GHVDC has taken care of the hard work of securing planning in principle, putting in the roads and services and made the whole process of buying a plot easier, thanks to its innovative plots shop.

This gives Self-building more accessible, giving more people the ability to buy a home that they can customise to suit their life and budget, or build from scratch on one of the many Self-build plots on offer. Expect to see more flying factories winging their way to you in the future.

Beattie Passive’s Flying Factory and workshop.